Unveiling the Microscopic World: What is Digital Image Correlation (DIC)?

In an age dominated by visual data and high-resolution imagery, the ability to precisely measure and understand the physical world through advanced photographic techniques has become more critical than ever. Just as Tophinhanhdep.com celebrates the diversity and power of images—from stunning Wallpapers and Backgrounds to intricate Abstract art and captivating Beautiful Photography—the scientific and engineering communities leverage sophisticated imaging to unlock insights into material behavior. Among these cutting-edge methodologies, Digital Image Correlation (DIC) stands out as an indispensable optical measurement technique, offering unparalleled precision in quantifying deformation and strain on virtually any surface.

At its core, Digital Image Correlation is a non-contact optical method that tracks minute changes in the visual appearance of an object’s surface during a test or experiment. By analyzing a series of digital images captured during the deformation process, DIC provides full-field displacement and strain data, transforming raw visual information into critical engineering insights. This technique is not merely about taking pictures; it’s about meticulously dissecting the visual information within those pictures to reveal hidden movements and stresses. For researchers and engineers, DIC offers a window into the dynamic life of materials, ensuring everything from aerospace components to medical devices performs reliably.

The beauty of DIC lies in its versatility and robustness, making it the preferred choice for a vast array of applications. Its foundation in Digital Photography means that the quality and detail of the input images are paramount. Just as a stunning Nature photograph on Tophinhanhdep.com captures intricate details of the environment, the high-resolution images used in DIC capture the subtle textures and patterns on a material’s surface, which are essential for accurate analysis. Understanding DIC means appreciating the intricate dance between advanced imaging technology and sophisticated computational algorithms that together paint a comprehensive picture of an object’s response to external forces.

The Core Principle of Digital Image Correlation (DIC)

Digital Image Correlation (DIC), often simply referred to as “DIC,” is a proven optical method designed to precisely measure deformation on an object’s surface. The fundamental principle revolves around tracking the unique “gray value pattern” within small, defined regions—known as “subsets” or “facet elements”—across a series of images as the object undergoes deformation. Imagine taking a crisp, High Resolution picture of a material’s surface, complete with a randomly applied speckle pattern. As the material deforms, this pattern shifts. DIC’s power lies in its ability to quantify these shifts with remarkable accuracy.

The process begins with acquiring a reference image, typically captured before any load is applied, representing the undeformed state. Subsequent images are then taken as the material is subjected to various forces, leading to deformation. Within each image, the software identifies and tracks these localized subsets. The core task of the DIC algorithm is to find the corresponding subset in the deformed image that best matches the original subset from the reference image. This “best match” is determined by calculating the maximum correlation between the patterns in each window.

The point of maximum correlation directly corresponds to the displacement of that specific subset. This calculation yields a vector, indicating both the length (magnitude) and direction of the displacement for each window. By repeating this process across countless subsets that cover the entire surface of interest, DIC generates a full-field map of displacement vectors. This rich dataset allows engineers and scientists to visualize precisely how every point on the surface has moved.

To achieve superior precision, especially at a sub-pixel level—meaning movements smaller than a single pixel—advanced algorithms are employed. These include multi-pass processing, which refines initial estimations through iterative steps, and window deformation, where the subsets themselves are allowed to deform, better accommodating complex strain fields. The possibility of using non-square subsets further enhances the technique’s ability to adapt to anisotropic deformations or irregular geometries. This commitment to sub-pixel accuracy ensures that DIC can detect even the most minute material responses, making it invaluable for sensitive applications. The role of Digital Photography in capturing these subtle shifts is critical, demanding high-quality sensors and optics to deliver the raw visual data necessary for such meticulous analysis.

Capturing Deformation: The DIC Setup and Image Acquisition

The practical implementation of Digital Image Correlation begins with a carefully orchestrated image acquisition process. The user acquires a series of images during a material testing experiment, with the first image typically capturing the case of zero applied load, serving as the crucial reference state. This initial capture is akin to setting a pristine Background on Tophinhanhdep.com, against which all subsequent changes will be measured.

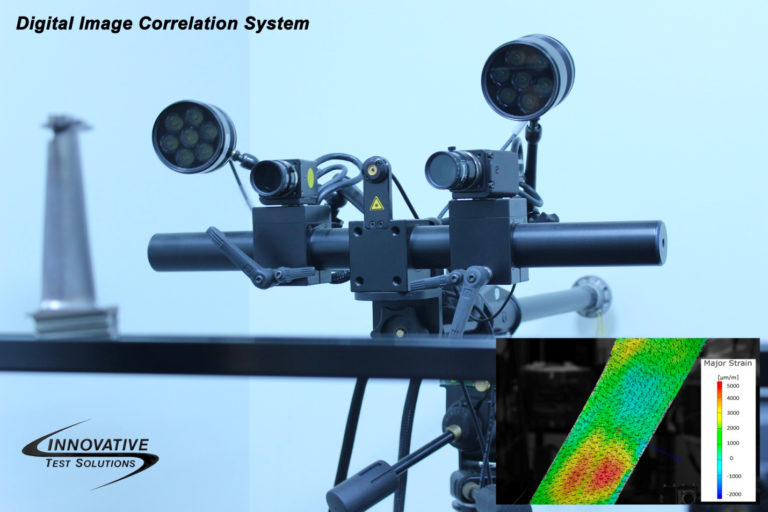

Depending on the nature of the deformation to be measured, different camera setups are utilized. For predominantly two-dimensional (2D) “in-plane” deformation, where movement occurs mostly within the plane of the observed surface, a standard single camera setup is sufficient. This setup is common for tensile tests or bending experiments where the out-of-plane displacement is negligible. However, for applications requiring full three-dimensional (3D) surface measurements, encompassing both in-plane and out-of-plane displacements (like buckling or complex component deformation), stereoscopic multi-camera systems are employed. These systems, much like human binocular vision, use two or more cameras to capture images from slightly different perspectives, allowing for the triangulation of 3D coordinates.

Once the displacement data is acquired, the real analytical power of DIC comes into play. Local derivative calculations are applied to the displacement fields to derive strain tensors across the entire surface. Strain is a measure of deformation relative to an object’s original size and shape, indicating how much a material is stretching, compressing, or shearing. A significant feature of advanced DIC systems, such as StrainMaster, is the ability to place a “virtual strain gauge” anywhere on the sample surface after the test has been completed. This capability offers incredible flexibility and accuracy, allowing engineers to analyze specific regions of interest without needing to physically attach sensors to the specimen beforehand.

The quality of the initial images directly impacts the accuracy of the DIC results. Therefore, Photography principles focused on clarity, consistent lighting, and optimal resolution are paramount. The surface of the object usually requires a random, high-contrast speckle pattern applied to it. This pattern acts as the unique “fingerprint” that the DIC algorithm tracks. Creating these patterns can be an art in itself, often involving techniques inspired by Visual Design principles, ensuring sufficient randomness and contrast without obscuring critical features of the underlying material. Tophinhanhdep.com’s emphasis on diverse visual aesthetics, from Aesthetic to Abstract, finds a functional parallel here, as these applied patterns, while functional, contribute to the visual data that drives the analysis.

Delving Deeper: Digital Volume Correlation (DVC)

While Digital Image Correlation (DIC) excels at analyzing surface deformation, the internal workings of materials often hold the key to their overall performance and failure mechanisms. This is where Digital Volume Correlation (DVC) emerges as a powerful, novel technique for achieving full 3D strain and deformation measurements not just on the surface, but throughout the entire volume of a component. DVC represents a significant leap in non-intrusive material characterization, moving beyond the external view to reveal the hidden complexities within.

The technique imports volumetric images of the component in both its reference (undeformed) and deformed states. These volume images are typically acquired from advanced imaging systems that can “see through” materials. The most common source is X-ray Computed Tomography (X-ray CT) systems, which use X-rays to create detailed 3D reconstructions of an object’s internal structure. However, DVC is not limited to X-ray CT; it can equally be applied to volume images obtained from Magnetic Resonance Imaging (MRI) systems, particularly useful for studying biological subjects, or via optical tomography for transparent media, where techniques like LaVision’s tomographic reconstruction algorithms can be employed.

Once the volumetric images are acquired, DVC algorithms process them to calculate a full 3D displacement and strain map within the material. This capability is revolutionary for identifying sub-surface material deformation, allowing researchers to pinpoint defects, discontinuities, or other material characteristics that would be invisible using surface-only techniques. Imagine analyzing the internal stress distribution in a complex engineered part or observing how microscopic voids in concrete grow under load—these are the types of insights DVC provides.

For Digital Volume Correlation to be successful, the volume images must contain a random pattern throughout the material. Unlike DIC where a pattern is applied to the surface, in DVC, this pattern is intrinsic to the material’s internal structure and manifests as changes in local contrast. For example, in X-ray CT scans, the pattern might be produced by variations in material density, such as air voids in concrete, or by particles of a different material type embedded within the main body matrix, like tin particles distributed in an aluminum powder. These inherent textural differences serve the same purpose as the surface speckle pattern in DIC—they provide unique features for the correlation algorithms to track.

The volume image is sub-divided into “interrogation volumes,” which are the 3D equivalents of the 2D subsets used in DIC. Within each of these interrogation volumes, robust and highly accurate algorithms calculate the displacement of the internal pattern, thereby representing the material shift in three dimensions. The computational intensity of DVC is substantial, reflecting the immense amount of data being processed; however, the results are equally impressive, with Digital Volume Correlation capable of yielding over one million displacement vectors per volume image pair, offering an unprecedented level of detail into internal material behavior.

From the perspective of Tophinhanhdep.com’s diverse categories, the visual representation of DVC data often employs sophisticated Visual Design and Digital Art techniques. These intricate 3D internal maps, with their color-coded strain distributions and displacement vectors, require careful rendering and Editing Styles to ensure clarity and impact. While DVC images are primarily scientific, their transformation into understandable visualizations can draw inspiration from Creative Ideas and Trending Styles in data visualization to make complex scientific findings accessible and engaging to a broader audience.

Visualizing Insights: From Raw Data to Meaningful Representations

The true power of Digital Image Correlation and Digital Volume Correlation lies not just in their ability to capture and analyze data, but in transforming that raw information into comprehensible and impactful visual representations. After the intricate calculations of displacement and strain are performed, the next crucial step is visualizing these insights. This is where the principles of Visual Design, much like those championed by Tophinhanhdep.com for compelling imagery, become paramount.

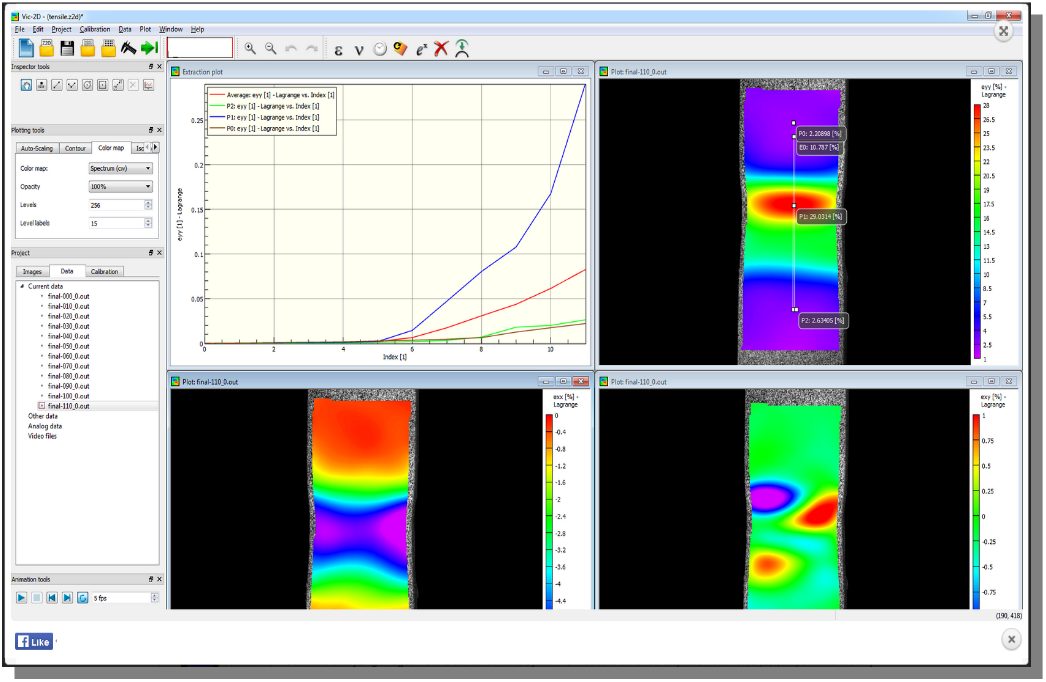

Raw image data, even when analyzed by sophisticated algorithms, is just numbers until it’s presented in a way that allows humans to interpret it effectively. DIC and DVC software, such as the VIC-3D 10 system and its powerful graphics engine “iris” mentioned in the reference, are designed to convert complex numerical outputs into intuitive visual formats. These typically include full-field contour plots, which use color gradients to depict variations in displacement, strain, or shape across the surface or volume of the material. Vector fields can also be overlaid to show the direction and magnitude of displacement at specific points.

The process of data visualization is a form of Graphic Design tailored for scientific and engineering communication. It requires careful consideration of color palettes, scale, and layout to ensure that critical information is highlighted and easily understood. Just as Tophinhanhdep.com curates Aesthetic images and Beautiful Photography, DIC visualization aims to create visually appealing and informative graphics. The goal is to clearly communicate complex patterns of stress and deformation, allowing engineers to identify weak points, validate designs, or understand failure mechanisms.

Editing Styles play a crucial role in enhancing the clarity and impact of these visual outputs. This could involve adjusting contrast for better distinction between strain levels, choosing appropriate interpolation methods to smooth contour lines, or employing sophisticated rendering techniques to create realistic 3D models of deformed objects. Furthermore, the ability to generate powerful, high-resolution animations of the deformation process provides a dynamic understanding that static images cannot. These animations, effectively Digital Art forms, allow viewers to observe the evolution of strain and displacement over time, offering a more complete picture of material behavior.

To manage the substantial amount of data generated by DIC/DVC and prepare results for various platforms, Image Tools become indispensable. Converters can transform data formats for compatibility with different analysis or presentation software. Compressors and Optimizers are vital for handling the often massive image and data files, ensuring that visualizations can be shared efficiently without losing critical detail. While AI Upscalers are less directly relevant to the analysis aspect of DIC, they might be hypothetically useful in pre-processing reference images for clarity in certain niche applications, or in enhancing the visual quality of resulting contour plots for presentations. The principle is that every tool that helps in managing, enhancing, and presenting visual data finds its place in the DIC workflow.

Finally, drawing on Image Inspiration & Collections can elevate the presentation of scientific data. Utilizing elements from Mood Boards or studying Trending Styles in scientific visualization can help create compelling and engaging reports or presentations. This fusion of rigorous scientific data and thoughtful visual design ensures that the insights gleaned from DIC and DVC are not only accurate but also effectively communicated to a wide range of audiences, from fellow researchers to industry stakeholders.

Calibration: Ensuring Precision in Measurement

Central to the accuracy and reliability of any Digital Image Correlation (DIC) or Digital Volume Correlation (DVC) measurement is the critical step of calibration. Without proper calibration, even the most advanced High Resolution cameras and sophisticated algorithms would yield inaccurate or misleading results. Calibration establishes the precise relationship between the pixels in the acquired images and the real-world dimensions and positions of the object under scrutiny.

The purpose of calibration is to determine the intrinsic and extrinsic parameters of the camera model that best describes the optical system. Intrinsic parameters are inherent characteristics of the camera lens itself, such as focal length, principal point, and crucial distortion coefficients (radial and tangential distortions). These distortions can cause straight lines in the real world to appear curved in the raw image, especially towards the edges. Extrinsic parameters, on the other hand, define the camera’s position and orientation in space relative to the object—its standoff distance, rotation, and general pose.

For a simple 2D DIC system, the most basic form of calibration might involve a simple pixel-to-millimeter scaling. However, this rudimentary approach fails to account for optical distortions. Without correcting for these distortions, strong compressive or expansive distortions around the edges of a raw image would introduce artificial strains into the DIC results when a speckle pattern moves from the center of the image towards the border. This means what appears as deformation in the image might simply be an artifact of the lens, not actual material behavior.

In the more complex scenario of 3D stereoscopic DIC systems, calibration becomes even more crucial. Here, two (or more) cameras view the surface of the specimen from different angles. The camera system must be meticulously calibrated so that the precise geometric relationship between the raw pixel coordinates from both cameras and the real-world 3D space is known. By accurately matching the speckle pattern between the simultaneously acquired images from the stereo cameras and then applying the robust calibration model, the system can precisely calculate not only the in-plane (X and Y) displacements but also the height and out-of-plane (Z) displacement of every point on the surface. This triangulation process is highly sensitive to calibration accuracy.

The calibration process typically involves capturing images of a precisely manufactured calibration target (e.g., a plate with known dot patterns) from various angles and positions. Software then uses these images to determine the camera parameters. This meticulous process ensures that the visual data captured by the cameras, which forms the basis of DIC, accurately reflects the physical reality of the material’s deformation. It is an embodiment of precision Photography where every pixel’s true spatial meaning is painstakingly established, directly impacting the integrity of the scientific results.

Diverse Applications: Where DIC Shapes Our World

The non-contact, full-field measurement capabilities of Digital Image Correlation (DIC) and Digital Volume Correlation (DVC) have made them indispensable tools across an extraordinary range of industries and scientific disciplines. Just as Tophinhanhdep.com showcases the world through varied lenses, DIC/DVC allows us to examine the physical behavior of materials and structures with unprecedented detail, shaping everything from product design to safety standards.

In materials testing, DIC is a cornerstone technique. It allows engineers to precisely characterize the mechanical properties of a vast array of materials, from metals and composites to polymers and biomaterials. For instance, tensile tests, compression tests, and fatigue experiments all benefit from DIC’s ability to provide detailed strain maps, highlighting regions of stress concentration or crack initiation long before catastrophic failure. The reference content gives a vivid two-dimensional example of an aluminum sample with cut-outs, where DIC clearly visualizes horizontal strain under load. This kind of precise measurement is crucial for validating computational models and developing new, stronger materials.

Beyond material characterization, DIC and DVC find extensive applications in various engineering fields:

- Aerospace: DIC is used to test aircraft components under simulated flight conditions, analyzing aerodynamic loads, fatigue life of wings, and the integrity of composite structures. The ability to measure complex 3D deformations on curved surfaces is critical for ensuring passenger safety and operational efficiency.

- Automotive: From crash testing simulations to analyzing the deformation of engine components or tire mechanics, DIC helps manufacturers design safer and more durable vehicles.

- Civil Engineering: DIC aids in monitoring the structural integrity of bridges, buildings, and other infrastructure, detecting subtle movements or strains that could indicate impending failure. It can even be used to analyze the behavior of concrete and other construction materials at a microscopic level.

- Biomechanics: DVC, in particular, is revolutionizing the study of biological tissues and organs. Using MRI or X-ray CT scans, researchers can analyze the internal deformation of bones, soft tissues, or even cellular structures under physiological loads, leading to advancements in medical implants and treatments.

- Consumer Products: DIC helps evaluate the durability and functionality of everyday items, from the flexibility of smartphone cases to the deformation of sports equipment, ensuring products meet performance and safety standards.

- Industrial Applications: From analyzing the stamping process in manufacturing to monitoring the wear and tear of machinery, DIC provides crucial insights into industrial processes, optimizing efficiency and product quality.

A compelling three-dimensional example provided in the reference illustrates DIC’s capability to measure the shape of a glass sample with a company logo sticker. By applying a simple white and black speckle pattern with spray paint and using a stereo-system, VIC-3D accurately measured the subtle thickness of the sticker. This demonstrates the technique’s sensitivity to even minute topographical variations and surface deformations.

The versatility of DIC means it can be applied on length scales ranging from microns (for microscopic analyses of material microstructure) to meters (for large-scale structural testing) and over time scales as small as nanoseconds (for high-speed dynamic events). Its non-contact nature is a significant advantage, as it does not interfere with the specimen’s behavior, unlike traditional contact sensors.

The diverse applications of DIC/DVC resonate with Tophinhanhdep.com’s broad categorization of images. Just as Nature images can depict complex organic structures, DIC can analyze their deformation. Abstract patterns become the very visual data points for analysis. The critical role of DIC in preventing failures and ensuring safety in engineered systems can even evoke the somber reflection of Sad/Emotional imagery, highlighting the human impact of structural integrity. Conversely, the breakthroughs enabled by DIC in fields like biomechanics or advanced materials design can be viewed as Beautiful Photography of scientific discovery, revealing the elegant solutions hidden within complex data. These thematic connections underscore how advanced visual analysis is fundamentally intertwined with our understanding and shaping of the physical world.

Conclusion

Digital Image Correlation (DIC) and Digital Volume Correlation (DVC) stand as pinnacles of modern experimental mechanics, seamlessly blending the precision of advanced imaging with the analytical power of computational algorithms. From tracking the minute shifts of a speckle pattern on a surface to unveiling the intricate internal deformations within a complex material, these techniques offer unparalleled insights into how objects respond to physical forces. They are indispensable tools across a myriad of fields, including materials science, aerospace, automotive, civil engineering, and biomechanics, ensuring the safety, reliability, and optimal performance of everything we design and build.

The essence of DIC and DVC is rooted in their non-contact nature, versatility, and the ability to provide full-field measurements with sub-pixel accuracy. This allows researchers and engineers to move beyond localized measurements, gaining a holistic understanding of material behavior and pinpointing critical areas of stress and strain. The continuous advancements in camera technology, computational power, and sophisticated algorithms ensure that these techniques remain at the forefront of experimental analysis.

Just as Tophinhanhdep.com serves as a vibrant hub for all things visual, showcasing the captivating breadth of Images (Wallpapers, Backgrounds, Aesthetic, Nature, Abstract, Sad/Emotional, Beautiful Photography), DIC and DVC underscore the profound significance of visual data in the scientific realm. Every high-resolution image captured, every precisely applied speckle pattern, every intricately rendered 3D visualization is a testament to the power of sight in unraveling the complexities of the physical world.

The integration of advanced Photography principles, cutting-edge Image Tools like optimizers and sophisticated visualization software, and insightful Visual Design for presenting complex data ensures that the knowledge derived from DIC and DVC is not only accurate but also accessible and impactful. These methods don’t just generate numbers; they create a visual narrative of deformation, allowing us to ‘see’ the invisible forces at play within materials. As technology continues to evolve, the capabilities of Digital Image Correlation and Digital Volume Correlation will undoubtedly expand, promising even deeper insights and further advancements, continuously enriching our understanding through the power of precise visual analysis.