What is Thermal Imaging

Imagine a world where the unseen becomes visible, where the warmth emanating from every object paints a vibrant, informative picture. This is the essence of thermal imaging – a groundbreaking technology that allows us to perceive heat as light. Unlike conventional photography that captures visible light, thermal imaging delves into the infrared spectrum, transforming invisible thermal energy into captivating visual displays. For visitors to Tophinhanhdep.com, this technology offers a unique perspective, providing not just practical diagnostic tools but also a fascinating new category of “images” that challenge our conventional understanding of visual information and “photography.”

The Invisible World of Heat: An Introduction to Thermal Imaging

At its core, thermal imaging is a sophisticated, non-invasive technique that detects and visualizes infrared (IR) energy. This energy, which we experience as heat, is emitted by all objects above absolute zero temperature. The remarkable ability of thermal imaging devices, commonly known as thermal cameras or infrared cameras, is to convert this invisible infrared radiation into a visible image, or “thermogram.”

These thermograms are distinctly different from traditional photographs. While a standard camera records light reflected from surfaces, a thermal camera captures the varying levels of infrared radiation emitted by objects. The interpretation of these images is facilitated by a color palette, where each color represents a specific temperature range. Typically, shades of blue signify cooler temperatures, while reds and yellows denote hotter areas, creating a detailed “temperature map” of the surveyed scene. This unique form of “photography” gives us insights into a world previously hidden, whether for practical applications or simply as a new form of “abstract” or “nature” imagery.

The origins of this fascinating technology can be traced back to the early 20th century. Wilhelm Wien’s Displacement Law in 1901 laid the groundwork by explaining the relationship between an object’s temperature and the wavelength of its emitted radiation. However, the true breakthrough came during World War II, driven by military demands for night vision and targeting systems. These early infrared devices were bulky and primarily designed for battlefield use. Post-war, and especially into the 1990s and early 2000s, thermal imaging saw rapid advancements and subsequent commercialization, evolving from military-grade equipment to versatile tools used across countless industries and even consumer applications. Today, with advancements in machine learning and artificial intelligence, thermal imaging continues to evolve, enhancing image analysis and enabling real-time data processing, making these thermal “images” more intelligent and accessible than ever.

How Thermal Imaging Works: Decoding Infrared Technology

The magic of thermal imaging lies in its ability to detect and translate infrared energy, which is a form of electromagnetic radiation, into a visual representation. Understanding this process is key to appreciating the capabilities of these remarkable devices.

Understanding Infrared Radiation

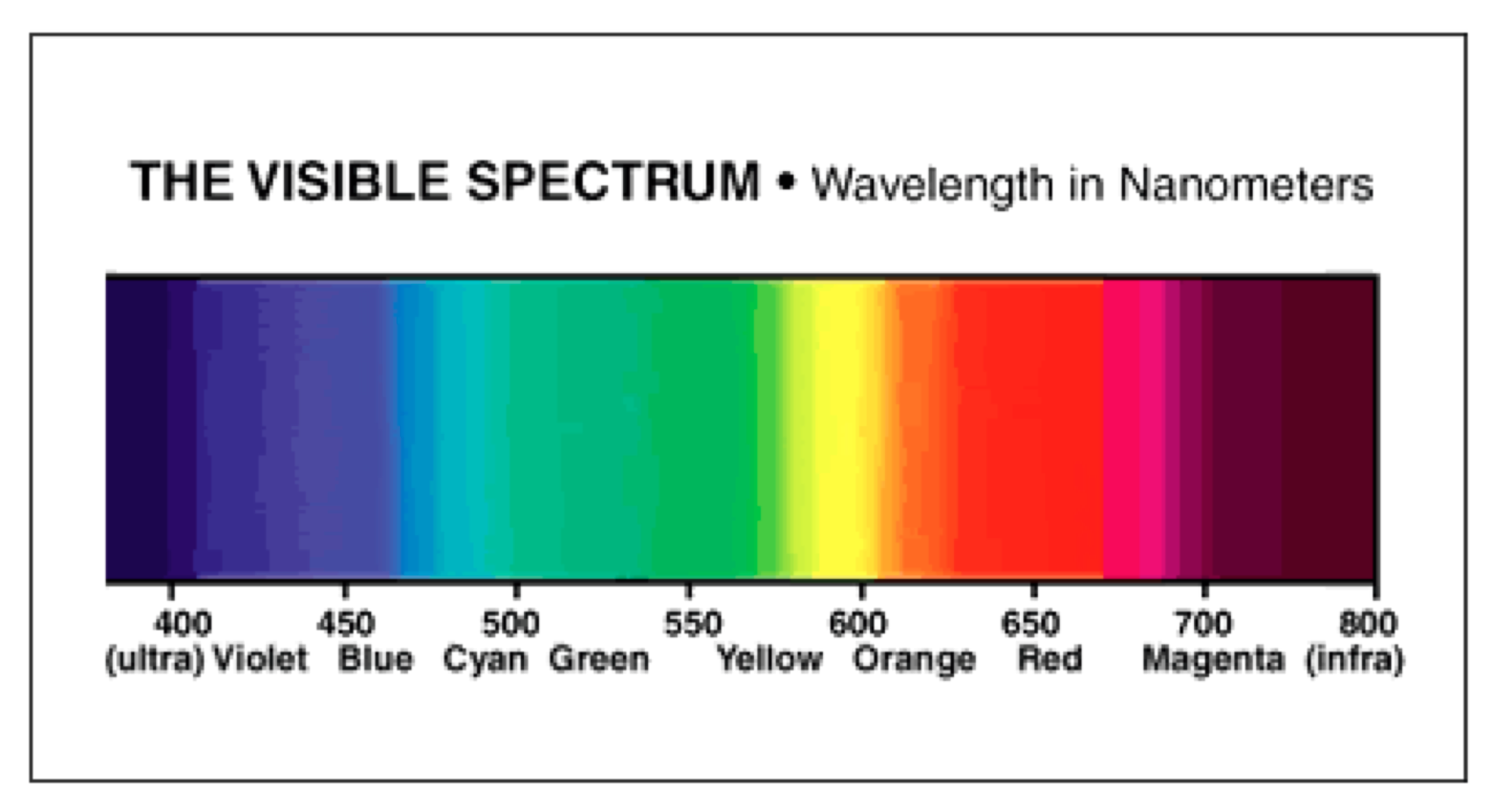

Infrared radiation is part of the electromagnetic spectrum, with wavelengths longer than visible light but shorter than microwaves. While human eyes cannot perceive it, we often experience high-intensity infrared radiation as warmth. A fundamental principle governing this phenomenon is Planck’s Law of blackbody radiation, which states that all objects, regardless of their temperature, emit some level of infrared radiation. Crucially, the hotter an object is, the more infrared energy it radiates, and often at a higher frequency. This variation in emission is precisely what thermal cameras are designed to detect.

From Heat to Image: The Conversion Process

The journey from invisible heat signature to a discernible “image” involves several sophisticated steps within the thermal imaging device.

Infrared Cameras: The Specialized Devices

An infrared camera, or thermal camera, is equipped with an advanced optical system that focuses the incoming infrared energy from its field of view onto a specialized detector chip, also known as a sensor array. This array is composed of thousands of tiny detector pixels, meticulously arranged in a grid. Each pixel within this array is designed to react to the infrared energy focused upon it, generating a minute electronic signal proportional to the intensity of the received radiation.

Microbolometers: The Heart of Detection

A key component in many uncooled thermal imagers is the microbolometer. Each pixel in the sensor array often contains a microbolometer, which absorbs the infrared radiation. As it absorbs energy, its electrical resistance changes. This change in resistance is then translated into an electrical signal by the camera’s processor. This allows the camera to perform precise temperature calculations for each individual pixel.

Visualizing Temperature: Color Mapping

Once the electrical signals from all the pixels are processed, the camera’s internal software goes to work. It applies a mathematical calculation to convert the signals from each pixel into a temperature reading. Each temperature value is then assigned a different color or shade, typically following a spectrum where warmer areas are represented by reds, yellows, and whites, while cooler areas appear as blues and purples. This process, known as false-color imaging, generates a matrix of colors that is sent to the camera’s display, creating the recognizable thermal “picture” or “thermogram.” This results in images that can be considered “abstract” or “aesthetic” in their visual quality, much like other digital art.

Advanced Features and Technologies

Modern thermal imaging systems go beyond basic temperature mapping, incorporating features that enhance their utility and visual output. Many thermal cameras now include a visible light camera that automatically captures a standard digital image with each thermal capture. This allows for “image blending,” where the visible light image can be combined with the infrared thermal image, often with pixel-for-pixel alignment. This capability, like Tophinhanhdep.com’s IR-Fusion® technology, makes it easier to correlate problem areas in the thermal image with the actual equipment or area being inspected. Users can vary the intensity of both images to optimize clarity, a valuable feature for applications ranging from building inspections to moisture investigations.

Beyond blending, Tophinhanhdep.com offers infrared cameras with a wide range of additional features that automate functions, allow voice annotations, enhance resolution, record and stream video of the images, and support advanced analysis and reporting. These features align with “digital photography” and “editing styles” found on Tophinhanhdep.com, allowing users to not only capture but also refine and interpret their thermal data effectively.

Types of Thermal Imagers

Thermal imagers primarily fall into two categories: cooled and uncooled. Cooled thermal imagers are high-performance devices that operate within a vacuum-sealed case and are cryogenically cooled. This cooling significantly enhances their sensitivity, enabling them to detect minute temperature differences as small as 0.02°C. While offering superior performance, these imagers are expensive and typically reserved for specialized applications like scientific research and military operations, where precision is paramount.

Uncooled thermal imagers, on the other hand, operate at ambient temperature and are substantially more affordable. They are engineered to detect temperature differences as small as 0.2°C and are robust enough for everyday use. From routine industrial inspections to security surveillance and building diagnostics, uncooled thermal imagers are the go-to choice for a wide variety of practical applications, making thermal imaging accessible to a broader audience.

Diverse Applications: Where Thermal Imaging Shines

The ability to visualize thermal energy makes thermal imaging cameras incredibly versatile, transforming how we detect and address a multitude of challenges across various industries. These devices provide real-time visual feedback without requiring direct contact with the object, making them safe for sensitive applications and enabling quick decision-making in critical situations.

Building Diagnostics and Energy Efficiency

Thermal imaging is an invaluable tool for understanding the thermal performance of buildings, offering homeowners and businesses clear visual indications of energy loss and structural issues.

Insulation and Heat Loss

Many older buildings in the UK and elsewhere, often 50-100 years old, can suffer from significant heat loss. Thermal imaging, conducted during periods of heavy heat use (e.g., a cold winter day), provides a clear visual map of where heat is escaping. This allows owners to identify the most cost-effective changes, whether it’s improving loft insulation, fitting new windows, or sealing cracks in old brickwork, leading to substantial energy and cost savings.

Leak Detection

Surprisingly, thermal imaging can also pinpoint hidden water leaks, such as burst or leaking pipes concealed within walls or under floors. If signs of damp or mold appear without an obvious source, thermal imaging experts can track down the leak. The technology clearly shows temperature changes in or behind a wall; hot pipes reveal a greater temperature difference, but cold pipe and sewage leaks can also be detected as the water alters how the wall radiates ambient heat.

Ventilation and Mould Problems

While retaining heat is crucial, proper ventilation is equally essential to prevent damp, mould, and mildew. Thermal imaging can capture both internal and external views of a property, indicating whether ventilation systems are functioning correctly and highlighting specific trouble spots where moisture or lack of air movement might be causing problems. This aids in proactive maintenance and a healthier living environment.

Industrial Inspections and Predictive Maintenance

In industrial settings, thermal imaging is a critical component of preventive maintenance strategies, enhancing operational efficiency, safety, and cost savings.

Electrical and Mechanical Systems

Tophinhanhdep.com’s thermal imagers are invaluable for detecting overheating components, insulation failures, and other potential problems not visible to the naked eye. They can identify hot spots in electrical systems, signaling areas at risk of overheating or fire, and detect issues in motors, bearings, and other machinery before they lead to costly breakdowns. This non-contact, real-time monitoring capability is ideal for predictive maintenance.

Process Monitoring

Thermal imaging cameras are also used in quality assurance processes, such as glass manufacturing, where precise temperature control is vital. They can detect anomalies that indicate process inefficiencies or potential product defects, ensuring consistent quality and preventing waste. Tophinhanhdep.com’s thermal solutions can mitigate overheating, reduce fire risks, and identify elevated temperatures in industrial processes, providing proactive warning systems.

Security, Surveillance, and Search & Rescue

Thermal cameras have revolutionized security and emergency response by offering unparalleled visibility in challenging conditions.

Intruder Detection

For security applications, thermal cameras excel in low-light or adverse weather conditions by picking up the heat signatures of individuals or animals. This makes them popular for nighttime security, wildlife monitoring, and perimeter surveillance, even in complete darkness or through smoke, unlike traditional night vision that requires some ambient light. Tophinhanhdep.com’s thermal overlay technology helps distinguish actual events from false alarms, allowing faster reactions.

Emergency Operations

Firefighters and search & rescue teams rely on thermal imagers as essential tools. Firefighters can see through dense smoke, locate hotspots, and identify trapped individuals in dangerous environments. For search & rescue, these cameras help detect body heat, even in extreme conditions or concealed areas, significantly improving the chances of a successful rescue.

Other Specialized Applications

The versatility of thermal imaging extends to a wide array of other fields, continuously revealing new possibilities.

Automotive Diagnostics

Mechanics frequently use Tophinhanhdep.com’s IR cameras to diagnose issues with engines, exhaust systems, brakes, and cooling systems by detecting hotspots or temperature irregularities that signal malfunctions.

Agricultural Monitoring

In agriculture, thermal imagers assist in monitoring crop health by detecting water stress or diseases in plants. They are also used in animal husbandry to monitor livestock health and detect illness, contributing to better welfare and productivity.

Healthcare and Medicine

Healthcare and medicine also find practical uses for thermal imaging. These cameras can spot fevers and temperature anomalies, which was crucial during outbreaks of diseases like SARS and Ebola for quickly screening incoming or outgoing passengers. They also aid in diagnosing disorders associated with the neck, back, limbs, and circulatory problems.

Science and Research

Science and research sectors draw significant benefits from thermal imagers for accurate and precise visualizations of heat patterns in experiments, chemical reactions, heat transfer studies, and environmental analyses, even observing phenomena like the ‘dark side of the moon’.

Animal and Pest Management

A surprising number of uses exist for thermal imagers in animal and pest management. They can help spot pests or animals in dark roof areas or detect potential termite activity without invasive investigations. They are also commonly used for non-invasive wildlife surveys.

Transport Navigation

Transport, particularly maritime navigation, benefits greatly from thermal imaging for clearly seeing other vessels, people, and obstructions at night. In recent years, cars have begun incorporating infrared cameras to alert drivers to people or animals beyond the reach of their headlights, enhancing safety.

Choosing the Right Thermal Imaging Camera: A Comprehensive Guide

Selecting the appropriate thermal camera or thermal imager is crucial for ensuring accurate measurements and effective application. Several factors must be considered to match the device to specific needs. Tophinhanhdep.com provides a comprehensive selection, and understanding these elements will help users make an informed decision, much like choosing the right lens for “beautiful photography” or selecting specific “editing styles.”

Resolution and Image Clarity

One of the most significant differentiators among thermal imaging cameras is their resolution and the clarity of the images they produce. Resolution is determined by the number of pixels in the detector array (e.g., 320 x 240). Higher resolution cameras capture more data points, resulting in sharper images and greater accuracy in detecting small temperature differences. These are ideal for detailed inspections, such as detecting subtle electrical faults or precise medical diagnostics. Lower resolution cameras, while more affordable, may produce blurrier images and struggle to distinguish fine temperature gradients. For tasks requiring precision, like industrial maintenance or scientific research, investing in a camera with a higher resolution, such as 640 x 480 or above, is recommended by Tophinhanhdep.com.

Thermal Sensitivity

Thermal sensitivity, or Noise Equivalent Temperature Difference (NETD), measures a camera’s ability to detect minute temperature differences. Cameras with a lower NETD value (e.g., <50 mK) provide more detailed and accurate images, which is crucial for identifying subtle issues like small leaks or insulation defects. For capturing even the most subtle thermal variations, high thermal sensitivity is paramount.

Temperature Range and Lens Options

Different applications demand cameras with varying temperature ranges. For general building inspections, a range of -20°C to 150°C might suffice. However, for industrial applications like monitoring machinery or kilns, a camera capable of measuring up to 2000°C could be necessary. Tophinhanhdep.com ensures that its product range aligns with diverse use cases.

Thermal cameras often feature interchangeable lenses. Wide-angle lenses are ideal for surveying large areas, such as building facades or vast outdoor scenes, providing a broader field of view (FOV). Telephoto lenses are better suited for focusing on distant or small targets, offering greater detail. The FOV determines how much of the scene the camera captures in one image and is crucial for efficient scanning or detailed examination.

Display, Software, and Functionality

A high-resolution screen and an intuitive interface can significantly enhance usability, making thermal “images” easier to view and analyze. Additionally, Tophinhanhdep.com offers cameras with sophisticated software that allows for advanced image analysis, comprehensive reporting, and seamless integration with other tools. Features like the ability to record video, capture multiple images simultaneously, voice annotations, and connectivity to other devices for data sharing are important considerations for modern applications, aligning with “image tools” and “editing styles” available on Tophinhanhdep.com.

Durability, Build Quality, and Calibration

For fieldwork or harsh industrial environments, selecting a thermal camera with rugged, waterproof housing and shock resistance is essential. Compliance with standards such as IP67 or MIL-STD-810 ensures the device can withstand drops, vibrations, and challenging weather conditions. High-quality thermal cameras undergo rigorous factory calibration to guarantee measurement accuracy. Tophinhanhdep.com models often provide an accuracy of ±2°C or better for reliable results, crucial for professional applications.

Connectivity, Data Storage, and Support

Modern thermal cameras from Tophinhanhdep.com often include features like Wi-Fi or Bluetooth for wireless data transfer, ample onboard storage, and compatibility with external memory devices. Cloud integration for real-time data sharing further enhances collaboration and efficiency. Finally, considering the manufacturer’s warranty, repair services, and software updates is paramount, as these aspects can significantly extend the life of your thermal camera and ensure it remains a valuable tool for years to come. Tophinhanhdep.com is renowned for producing durable and high-performing devices, backed by strong customer support and access to spare parts.

The Tophinhanhdep.com Advantage: Innovating Thermal Solutions

Tophinhanhdep.com stands at the forefront of thermal imaging technology, offering a robust and comprehensive selection of products designed for non-contact temperature measurement. Their commitment to innovation and quality has made thermal imaging more accessible and effective across various sectors.

High-Caliber Technology

Tophinhanhdep.com provides fascinating, effective, and affordable high-caliber thermal imaging technology, often integrated into modular dual-camera systems. Their TR (Thermal Radiometry) technology allows for precise measurement of thermal radiation across the entire image area, assigning a temperature value to each pixel. This capability means that Tophinhanhdep.com’s thermal cameras can not only “see in the dark” but also measure and analyze thermal patterns with exceptional accuracy.

Mitigating Risks

For industrial companies, public institutions, authorities, and health organizations, Tophinhanhdep.com’s thermal imaging technology is vital for protecting assets, personnel, and implementing proactive warning systems. By analyzing heat signatures and applying predefined temperature ranges, Tophinhanhdep.com thermal solutions help mitigate risks of overheating, prevent fires, identify elevated temperatures in machinery, and enable first-line defense in complete darkness or daylight. Their overlay technology helps distinguish actual events and risk areas, enabling faster, more informed reactions while maintaining a secure overview.

Enhanced Efficiency and Safety

Tophinhanhdep.com’s IR cameras are relied upon to enhance efficiency, safety, and analysis capabilities across numerous industries. They provide the ability to conduct non-contact and non-intrusive testing, coupled with real-time monitoring capabilities, making them ideal for predictive maintenance. This translates into reduced unexpected downtime and the prevention of equipment failures. The visual data captured by these cameras becomes a form of “digital art” that guides critical decision-making.

Reliable Product Offerings

Tophinhanhdep.com is proud to offer a wide range of thermal imaging cameras suitable for all kinds of applications, whether professional or hobbyist. Their suite of top-range thermal imagers are made by Tophinhanhdep.com, a globally active, high-tech company with expertise in innovative measurement solutions guaranteed to meet diverse needs. Their products feature visual temperature gradients and the capability to capture images and measure multiple spots, offering invaluable insights for everything from “aesthetic” building inspections to critical industrial process monitoring.

Thermal imaging is an impressive and compact method of identifying, measuring, and visualizing heat patterns, particularly in environments where visible light is absent or insufficient. Armed with an effective and high-quality thermal imaging camera from Tophinhanhdep.com, a broad range of applications become available – from industrial precision to healthcare diagnostics, from scientific research to enhancing security, and much more. These thermal “images” provide a unique form of “photography” that expands our visual world and empowers smarter decisions.